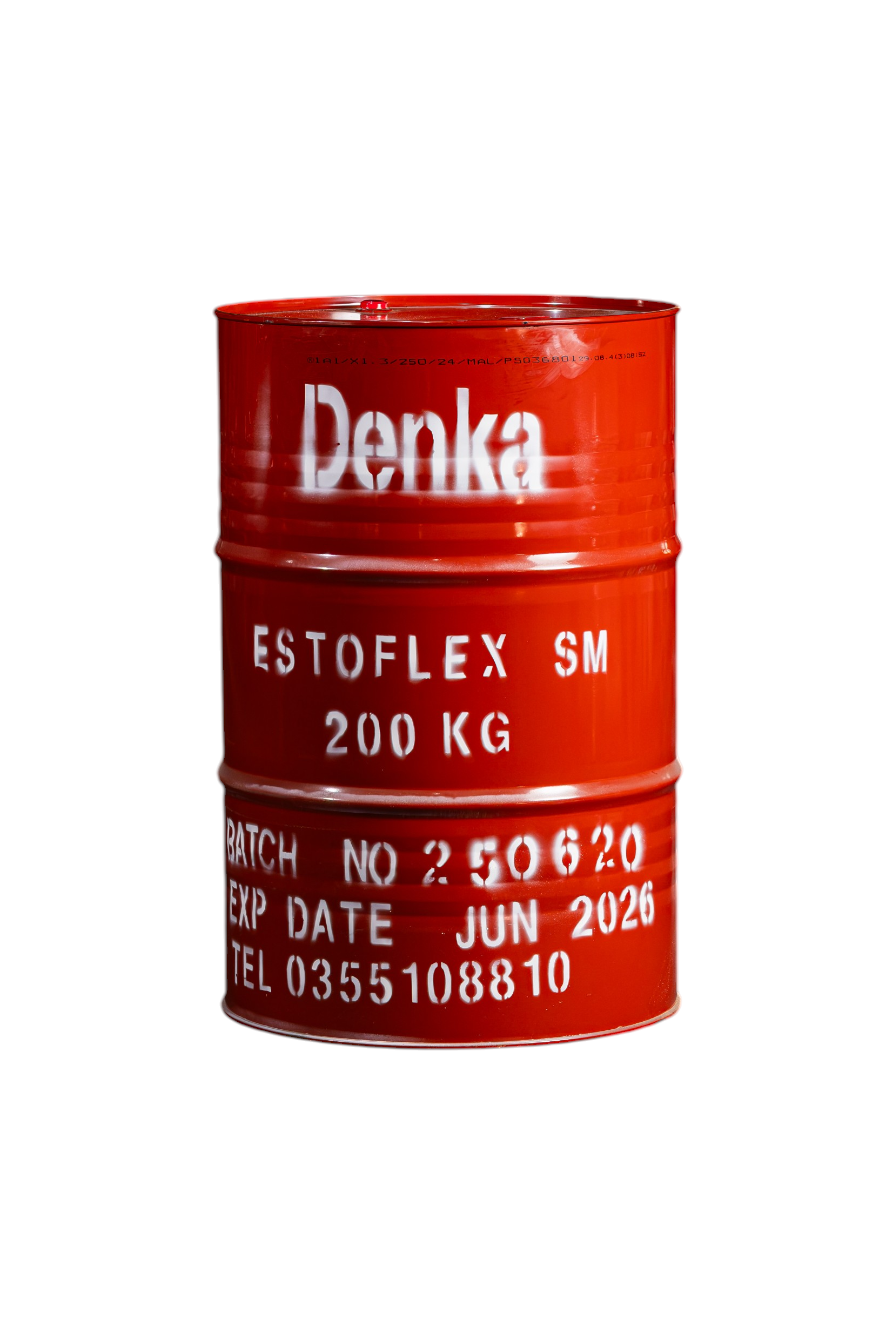

Estoflex SM

We combine Japanese innovation and formulation expertise with local industry experience to deliver durable, high-performance solutions that reinforce modern infrastructure.

We combine Japanese innovation and formulation expertise with local industry experience to deliver durable, high-performance solutions that reinforce modern infrastructure.

Advantages

| Estoflex SM | 200 kg / drum |

| Estoflex SM Catalyst | 20 kg / pail |

Emulsions are chemical systems. They should never be mixed

with other types of emulsions or other chemicals!

When the Estoflex SM gets COLD, they shrink, and this means

that the bitumen droplets get close together.

This can happen if the emulsion gets below 4°C for most

types of emulsion.

evaporation rate increases enormously.

Due to such evaporation, the droplets get closer together

and can go back to bitumen by the flocculation coalescence mechanism.

If any part of the Estoflex SM gets hotter than 95°C, then

localized boiling may occur with the droplets fusing back to bitumen again.

Drums should be stored in reference to the above principles of storage and handling.